GRAVITY SKETCH

GRAVITY SKETCH

Virtual Reality (VR) technology promised to make it possible for designers to 'see' new cars, factories and houses before they had been even built. With new high-quality headsets and software, that vision is closer to coming true.

Most designs used to start with an idea, a pen and some paper.

Now, imagine conjuring 3D shapes out of thin air and sharing your life-like designs in real time with people half way around the world.

The whole process of designing a new product becomes faster, cheaper and more effective. VR is finally beginning to fulfil its potential for business.

AUDI

AUDI

"You can walk around your sketches so you can see how your lines work in a 3D environment, and move freely in a room," explains Jan Pflueger, augmented and virtual reality co-ordinator for German car firm Audi.

In the past, the technology - hardware, software, connectivity - simply wasn't up to the job.

"Designers didn't like using headsets because the image resolution was too low," says Mr Pflueger.

Not only were the images poor quality, the headsets were heavy and uncomfortable to wear.

But now that processing speeds have increased and optics tech has improved, we're reaching the stage where VR is coming close to the limits of what the human eye can perceive.

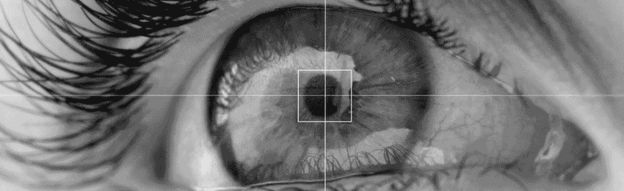

For example, Audi is working with Finnish start-up Varjo, which has recently starting selling a high-end (€5,995; £5,170) headset boasting "human eye resolution" using a technique called "foveated rendering".

VARJO

VARJO

It uses eye-tracking technology to tell which part of the image you're focusing on, then concentrates its processing power on that section to render it in high definition.

So you perceive the highest quality without having to process the entire image in high definition for every frame, which would require huge computing resources.

"In the beginning, designers hadn't been able to view their designs properly, but now they can walk around cars or other objects in life size," explains Niko Eiden, Varjo chief executive.

And because the image quality is so good, car designers can experiment with different materials for seats, dashboards and so on without having to make expensive physical models, says Mr Pflueger.

"This speeds up the design process because they can make decisions about how designs should be modified at a very early stage," he adds.

VARJO

VARJO

Designing a car or aeroplane is a laborious process, involving hundreds of iterations, physical models, wind-tunnel testing - all of which takes time and a lot of money. High-quality VR is removing many of these steps and cutting costs as a result, says Mr Pflueger.

And it is newcomers like Varjo and Pimax that are challenging the established leaders, such as HTC and HP, in the high-end business VR headset market, says David Nahon, head of immersive VR at French software firm, Dassault Systemes.

Dassault specialises in software to create 3D VR images, along with companies such as Gravity Sketch and Masterpiece VR.

"When you see the images at life-size scale you have much more empathy with the end user of your design, because you're in his or her shoes. You trigger different neurons," says Mr Nahon.

And the fact that people can consult with clients and collaborate with other designers in these shared virtual spaces also improves the efficiency of the design process, he adds.

GETTY IMAGES

GETTY IMAGES

It also enables the creation of "digital twins" of industrial equipment, aero engines, even human organs, enabling specialists to diagnose issues more accurately in a life-life 3D environment, he says.

It can work for customers as well as designers. Homebuyers could look around yet-to-be-built apartments, for example, and choose the combination of colours, carpets, furniture and kitchens that they like. Similarly with car buyers in the showroom.

And being able to visualise and discuss the huge amounts of data we have now in 3D is helping researchers spot patterns and anomalies they never would have spotted before, argues Marty Resnick, VR specialist at research firm Gartner.

No comments:

Post a Comment