- FORD BLUNDERS AGAIN WITH THE BARRA ENGINE LIKE IN 1969 WITH THE WINNING GT-40.

- ALMOST A HALF A CENTURY LATER, THEY REALIZE THEIR FOLLY AND COMMIT ANOTHER SIN BY BRINGING BACK A FAKE GT-40 WITH A V6 INSTEAD OF A V8.THE CURRENT GT-40 WOULD HAVE BEEN UNBEATABLE IF IT FEATURED A DOUBLE BARREL BARRA TURBO.

The Ford GT40 is an American high-performance endurance racing car. The Mk I, Mk II, and Mk III variants were designed and built in England based upon the British Lola Mk6. Only the Mk IV model was designed and built in the United States. The range was powered by a series of American-built Ford V8 engines modified for racing.

The GT40 effort was launched by Ford Motor Company to win long-distance sports car races against Ferrari, which won every 24 Hours of Le Mans race from 1960 to 1965. The GT40 broke Ferrari's streak in 1966 and went on to win the next three annual races. The Mk II's victory was the first win for an American manufacturer in a major European race since Jimmy Murphy's triumph with Duesenberg at the 1921 French Grand Prix.[5][6] In 1967, the Mk IV became the only car designed and built entirely in the United States to achieve the overall win at Le Mans.[7]

The Mk 1, the oldest of the cars, won in 1968 and 1969, the second chassis to win Le Mans more than once. (This Ford/Shelby chassis #P-1075 was believed to have been the first until the Ferrari 275P chassis 0816 was revealed to have won the 1964 race after winning the 1963 race in 250P configuration and with a 0814 chassis plate[8]). Using an American Ford V8 engine, originally of 4.7-liter displacement capacity (289 cubic inches), it was later enlarged to the 4.9-liter engine (302 cubic inches), with custom alloy Gurney–Weslake cylinder heads.

Early cars were simply named "Ford GT" for Grand Touring), the name of Ford's project to prepare the cars for the international endurance racing circuit. The "40" represented its height of 40 inches (1.02 m), measured at the windshield, the maximum allowed. The first 12 "prototype" vehicles carried serial numbers GT-101 to GT-112. The "production" began and the subsequent cars: the MkI, MkII, MkIII, and MkIV were numbered GT40P/1000 through GT40P/1145, and thus officially "GT40s". The Mk IVs were numbered J1-J12.

The contemporary Ford GT is a modern homage to the GT40.

History[edit]

Henry Ford II had wanted a Ford at Le Mans since the early 1960s. In early 1963, Ford reportedly received word through a European intermediary that Enzo Ferrari was interested in selling to Ford Motor Company. Ford reportedly spent several million dollars in an audit of Ferrari factory assets and in legal negotiations, only to have Ferrari unilaterally cut off talks at a late stage due to disputes about the ability to direct open-wheel racing. Ferrari, who wanted to remain the sole operator of his company's motorsports division, was angered when he was told that he would not be allowed to race at the Indianapolis 500 if the deal went through since Ford fielded Indy cars using its own engine, and didn't want competition from Ferrari. Enzo cut the deal off out of spite and Henry Ford II, enraged, directed his racing division to find a company that could build a Ferrari-beater on the world endurance-racing circuit.[9]

To this end Ford began negotiation with Lotus, Lola, and Cooper. Cooper had no experience in GT or prototype and its performances in Formula One were declining.[10]

The Lola proposal was chosen since Lola had used a Ford V8 engine in its mid-engined Lola Mk6 (also known as Lola GT). It was one of the most advanced racing cars of the time, and made a noted performance in Le Mans 1963, even though the car did not finish, due to low gearing and slow revving out on the Mulsanne Straight. However, Eric Broadley, Lola Cars' owner and chief designer, agreed on a short-term personal contribution to the project without involving Lola Cars.[11]

The agreement with Broadley included a one-year collaboration between Ford and Broadley, and the sale of the two Lola Mk 6 chassis builds to Ford. To form the development team, Ford also hired the ex-Aston Martin team manager John Wyer.[12] Ford Motor Co. engineer Roy Lunn was sent to England; he had designed the mid-engined Mustang I concept car powered by a 1.7-liter V4. Despite the small engine of the Mustang I, Lunn was the only Dearborn engineer to have some experience with a mid-engined car.

Overseen by Harley Copp, the team of Broadley, Lunn, and Wyer began working on the new car at the Lola Factory in Bromley. At the end of 1963, the team moved to Slough, near Heathrow Airport. Ford then established Ford Advanced Vehicles (FAV) Ltd, a new subsidiary under the direction of Wyer, to manage the project.[12]

The first chassis built by Abbey Panels of Coventry was delivered on 16 March 1964, with fiber-glass moldings produced by Fibre Glass Engineering Ltd of Farnham. The first "Ford GT" the GT/101 was unveiled in England on 1 April and soon after exhibited in New York. Purchase price of the completed car for competition use was £5,200.[13]

It was powered by the 4.7 L 289 cu in Fairlane engine with a Colotti transaxle, the same power plant was used by the Lola GT and the single-seater Lotus 29 that came in a highly controversial second at the Indy 500 in 1963.[14] (An aluminum block DOHC version, known as the Ford Indy Engine, was used in later years at Indy.[15] It won in 1965 in the Lotus 38.)

Racing history[edit]

The Ford GT40 was first raced in May 1964 at the Nürburgring 1000 km race where it retired with suspension failure after holding second place early in the event. Three weeks later at the 24 Hours of Le Mans, all three entries retired although the Ginther/Gregory car led the field from the second lap until its first pitstop. After a season-long series of dismal results under John Wyer in 1964, the program was handed over to Carroll Shelby after the 1964 Nassau race. The cars were sent directly to Shelby, still bearing the dirt and damage from the Nassau race. Carroll Shelby was noted for complaining that the cars were poorly maintained when he received them, but later information revealed the cars were packed up as soon as the race was over, and FAV never had a chance to clean and organize the cars to be transported to Shelby.

Shelby's first victory came on their maiden race with the Ford program, with Ken Miles and Lloyd Ruby taking a Shelby American-entered Ford GT40 [16] to victory in the Daytona 2000 in February 1965. One month later Ken Miles and Bruce McLaren came in second overall (to the winning Chaparral in the sports class) and first in prototype class at the Sebring 12-hour race. The rest of the season, however, was a disappointment.

The experience gained in 1964 and 1965 allowed the 7-liter Mk II to dominate the following year. In February, the GT40 again won at Daytona. This was the first year Daytona was run in the 24 Hour format and Mk II's finished 1st, 2nd, and 3rd. In March, at the 1966 12 Hours of Sebring, GT40s again took all three top finishes with the X-1 Roadster first, an Mk. II taking second, and an Mk. I in third. Then in June at the 24 Hours of Le Mans the GT40 achieved yet another 1–2–3 result.

The Le Mans finish, however, was clouded in controversy: The No1 car of Ken Miles and Denny Hulme held a four lap lead over the No2 car of Bruce McLaren and Chris Amon. This disintegrated when the No1 car was forced to make a pit-stop for replacement brake rotors, following an incorrect set being fitted a lap prior in a scheduled rotor change. It was found to be a result of the correct brake rotors being taken by the No2 crew. [17] This meant, that in the final few hours, the Ford GT40 of New Zealanders Bruce McLaren and Chris Amon closely trailed the leading Ford GT40 driven by Englishman Ken Miles and New Zealander Denny Hulme. With a multimillion-dollar program finally on the very brink of success, Ford team officials faced a difficult choice. They could allow the drivers to settle the outcome by racing each other—and risk one or both cars breaking down or crashing. They could dictate a finishing order to the drivers—guaranteeing that one set of drivers would be extremely unhappy. Or they could arrange a tie, with the McLaren/Amon and Miles/Hulme cars crossing the line side-by-side.

The team chose the last and informed McLaren and Miles of the decision just before the two got in their cars for the final stint. Then, not long before the finish, the Automobile Club de l'Ouest (ACO), organizers of the Le Mans event, informed Ford that the geographical difference in starting positions would be taken into account at a close finish. This meant that the McLaren/Amon vehicle, which had started perhaps 60 feet (18 m) behind the Hulme-Miles car, would have covered slightly more ground over the 24 hours and would, therefore, be the winner. Secondly, Ford officials admitted later, the company's contentious relationship with Miles, its top contract driver, placed executives in a difficult position. They could reward an outstanding driver who had been at times extremely difficult to work with, or they could decide in favor of drivers (McLaren/Amon) who had committed less to the Ford program but who had been easier to deal with. Ford stuck with the orchestrated photo finish but Miles, deeply bitter over this decision after his dedication to the program, issued his own protest by suddenly slowing just yards from the finish and letting McLaren across the line first. Miles died in a testing accident in the J-car (later to become the Mk IV) at Riverside (CA) Raceway just two months later.

Miles' death occurred at the wheel of the Ford "J-car", an iteration of the GT40 that included several unique features. These included an aluminum honeycomb chassis construction and a "bread van" body design that experimented with "Kammback" aerodynamic theories. Unfortunately, the fatal Miles accident was attributed at least partly to the unproven aerodynamics of the J-car design, as well as the experimental chassis' strength. The team embarked on a complete redesign of the car, which became known as the Mk IV. The Mk IV, newer design with an Mk II engine but a different chassis and a different body, won the following year at Le Mans (when four Mark IVs, three Mark IIs, and three Mark Is raced). The high speeds achieved in that race caused a rule change, which already came in effect in 1968: the prototypes were limited to the capacity of 3.0 liters, the same as in Formula One. This took out the V12-powered Ferrari 330P as well as the Chaparral and the Mk. IV.

If at least 50 cars had been built, sportscars like the GT40 and the Lola T70 were allowed, with a maximum of 5.0 L. John Wyer's revised 4.7-liter (bored to 4.9 liter, and O-rings cut and installed between the block and head to prevent head gasket failure, a common problem found with the 4.7 engine) Mk I won the 24 hours of Le Mans race in 1968 against the fragile smaller prototypes. This result added to four other round wins for the GT40, gave Ford victory in the 1968 International Championship for Makes. The GT40's intended 3.0 L replacement, the Ford P68, and Mirage cars proved a dismal failure. While facing more experienced prototypes and the new yet still unreliable 4.5 L flat-12-powered Porsche 917s, Wyer's 1969 24 Hours of Le Mans winners Jacky Ickx/Jackie Oliver managed to beat the remaining 3.0-liter Porsche 908 by just a few seconds with the already outdated GT40 Mk I, in the very car that had won in 1968—the legendary GT40P/1075. Apart from brake wear in the Porsche and the decision not to change brake pads so close to the race end, the winning combination was relaxed driving by both GT40 drivers and heroic efforts at the right time by (at that time Le Mans' rookie) Ickx, who won Le Mans five more times in later years.

Le Mans 24 Hour victories[edit]

| Le Mans 24 Hour victories | ||||||||

|---|---|---|---|---|---|---|---|---|

| Distance | Speed | |||||||

| Year | Car | Team | Drivers | Engine | Tire/Tyre | km | mph | km/h |

| 1966[18] | GT40P/1046 (Mk II) | Ford 7.0L V8 | G | 4843.09 | 125.39 | 201.80 | ||

| 1967 | J5 (Mk IV) | Ford 7.0L V8 | G | 5232.9 | 135.48 | 218.03 | ||

| 1968 | GT40P/1075 (Mk I) | Ford 4.9 L V8 | F | 4452.88 | 115.29 | 185.54 | ||

| 1969 | GT40P/1075 (Mk I) | Ford 4.9 L V8 | F | 4997.88 | 129.40 | 208.25 | ||

International titles[edit]

In addition to four consecutive overall Le Mans victories, Ford also won the following four FIA international titles (at what was then unofficially known as the World Sportscar Championship) with the GT40:

- 1966 International Manufacturers Championship – Over 2000cc

- 1966 International Championship for Sports Cars – Division III (Over 2000cc)

- 1967 International Championship for Sports Cars – Division III (Over 2000cc)

- 1968 International Championship for Makes

Versions[edit]

Mk I[edit]

The Mk.I was the original Ford GT40. Early prototypes were powered by 4.2 L (255 cu in) alloy V8 engines [19] and production models were powered by 289 cu in (4.7 L) engines as used in the Ford Mustang. Five prototype models were built with roadster bodywork, including the Ford X-1.[1] Two lightweight cars (of a planned five) were built by Alan Mann Racing in 1966, with light alloy bodies and other weight-saving modifications.

The Mk.I met with little success in its initial tune for the 1964 and 1965 Le Mans races. The first success came after their demise at the Nassau Speed Weekend Nov 1964 when the racing was handed over to Carrol Shelby. Shelby's team modified the Ford GT40 and the first win at Daytona February 1965 was achieved. Much was later modified and run by John Wyer in 1968 and 1969, winning Le Mans in both those years and Sebring in 1969. The Mk.II and IV were both obsolete after the FIA had changed the rules to ban unlimited capacity engines, ruling out the 7.0 L (427 cu in) Ford V8. However, the Mk.I, with its smaller engine, was legally able to race as a homologated sports car because of its production numbers.

In 1968 competition came from the Porsche 908 which was the first prototype built for the 3-liter Group 6. The result of the 1968 was resounding success at the 24 Hours of Le Mans with Pedro Rodríguez and Lucien Bianchi having a clear lead over the Porsches, driving the almighty #9 car with the 'Gulf Oil' colors.[20] The season began slowly for JW, losing at Sebring and Daytona before taking their first win at the BOAC International 500 at Brands Hatch. Later victories included the Grand Prix de Spa, 21st Annual Watkins Glen Sports Car Road Race and the 1000 km di Monza.[21] The engine installed on this car was a naturally aspirated Windsor 302 cu in (4.9 L) V8 engine with a compression ratio of 10.6:1 fuel feed by four 2-barrel 48 IDA Weber carburetors, rated at 425 hp (431 PS; 317 kW) at 6,000 rpm and a maximum torque of 395 lb⋅ft (536 N⋅m) at 4,750 rpm.[22]

31 Mk I cars were built at the Slough factory in "road" trim, which differed little from the race versions. Wire wheels, carpet, ruched fabric map pockets in the doors and a cigarette lighter made up most of the changes. Some cars deleted the ventilated seats, and at least one (chassis 1049) was built with the opening, metal-framed, windows from the Mk III.

- X-1 Roadster

The X-1 was a roadster built to contest the Fall 1965 North American Pro Series, a forerunner of Can-Am, entered by the Bruce McLaren team and driven by Chris Amon. The car had an aluminum chassis built at Abbey Panels and was originally powered by a 4.7-liter (289 ci) engine. The real purpose of this car was to test several improvements originating from Kar Kraft, Shelby, and McLaren. Several gearboxes were used: a Hewland LG500 and at least one automatic gearbox. It was later upgraded to Mk.II specifications with a 7.0-liter (427 ci) engine and a standard four ratio Kar Kraft (subsidiary of Ford) gearbox, however, the car kept specific features such as its open roof and lightweight aluminum chassis. The car went on to win the 12 Hours of Sebring in 1966. The X-1 was a one-off and having been built in the United Kingdom and being liable for United States tariffs, was later ordered to be destroyed by United States customs officials.[23]

Mk II[edit]

The Mk.II was very similar in appearance to the Mk.I but used the 7.0-liter FE (427 ci) engine from the Ford Galaxie, used in NASCAR at the time and modified for road course use. The car's chassis was similar to the British-built Mk.I chassis, but it and other parts of the car had to be redesigned and modified by Shelby to accommodate the larger and heavier 427 engine. A new Kar Kraft-built four-speed gearbox replaced the ZF five-speed used in the Mk.I. This car is sometimes called the Ford Mk.II.

In 1966, the Mk.II dominated Le Mans with Ken Miles taking European audiences by surprise and beating Ferrari to finish 1-2-3 in the standings. After the success of these Mk.II cars, the Ford GT40 went on to win the race for the next three years.

For 1967, the Mk.IIs were upgraded to "B" spec; they had re-designed bodywork and twin Holley carburetors for an additional 15 hp. A batch of improperly heat-treated input shafts in the transaxles sidelined virtually every Ford in the race at Daytona, however, and Ferrari won 1-2-3. The Mk.IIBs were also used for Sebring and Le Mans that year and won the Reims 12 Hours in France. For the Daytona 24 Hours, two Mk II models (chassis 1016 and 1047) had their engines re-badged as Mercury engines; Ford seeing a good opportunity to advertise that division of the company. [24]

Mk III[edit]

The Mk III was a road-car only, of which seven were built.[1] The car had four headlamps, the rear part of the body was expanded to make room for luggage, the 4.7-liter engine was detuned to 306 bhp (228 kW), the shock absorbers were softened, the shift lever was moved to the center, an ashtray was added, and the car was available with the steering wheel on the left side of the car. As the Mk III looked significantly different from the racing models many customers interested in buying a GT40 for road use chose to buy a Mk I that was available from Wyer Ltd. Of the seven MK III that were produced four were left-hand drive.

J-car[edit]

In an effort to develop a car with better aerodynamics (potentially resulting in superior control and speed compared to competitors), the decision was made to re-conceptualize, and redesign everything about the vehicle other than its powerful 7-liter Engine. This would end up resulting in the abandonment of the original Mk.I/Mk.II chassis. In order to bring the car into alignment with Ford’s "in house" ideology at the time, more restrictive partnerships were implemented with English firms, which resulted in the sale of Ford Advanced Vehicles, (acquired by John Wyer) ultimately leading to a new vehicle which would be slated for design by Ford's studios and produced by Ford's subsidiary Kar-Kraft under Ed Hull. Furthermore there was also a partnership with the Brunswick Aircraft Corporation for expertise on the novel use of aluminum honeycomb panels bonded together to form a lightweight, rigid "tub". The car was designated as the J-car, as it was constructed to meet the new Appendix J regulations [25] which were introduced by the FIA in 1966.[26]

The first J-car was completed in March 1966 and set the fastest time at the Le Mans trials that year. The tub weighed only 86 lb (39 kg), and the entire car weighed only 2,660 lb (1,207 kg), 300 lb (136 kg) less than the Mk II. It was decided to run the Mk IIs due to their proven reliability, however, and little or no development was done on the J-car for the rest of the season. Following Le Mans, the development program for the J-car was resumed, and a second car was built. During a test session at Riverside International Raceway in August 1966 with Ken Miles driving, the car suddenly went out of control at the end of Riverside's high-speed, 1-mile-long back straight. The aluminum honeycomb chassis did not live up to its design goal, shattering upon impact. The car burst into flames, killing Miles. It was determined that the unique, flat-topped "bread van" aerodynamics of the car, lacking any sort of spoiler, were implicated in generating excess lift. Therefore, a conventional but significantly more aerodynamic body was designed for the subsequent development of the J-car which was officially known as the Mk IV.[27] A total of nine cars were constructed with J-car chassis numbers although six were designated as Mk IVs and one as the G7A.[1]

Mk IV[edit]

The Mk IV was built around a reinforced J chassis powered by the same 7.0 L engine as the Mk II. Excluding the engine, gearbox, some suspension parts and the brakes from the Mk.II, the Mk.IV was totally different from other GT40s, using a specific, all-new chassis and bodywork. It was undoubtedly the most radical and American variant of all the GT40's over the years. As a direct result of the Miles accident, the team installed a NASCAR-style steel-tube roll cage in the Mk.IV, which made it much safer, but the roll cage was so heavy that it negated most of the weight saving of the then-highly advanced, radically innovative honeycomb-panel construction. The Mk. IV had a long, streamlined shape, which gave it exceptional top speed, crucial to do well at Le Mans in those days (a circuit made up predominantly of straights)—the race it was ultimately built for. A 2-speed automatic gearbox was tried, but during the extensive testing of the J-car in 1966 and 1967, it was decided that the 4-speed from the Mk.II would be retained. Dan Gurney often complained about the weight of the Mk.IV, since the car was 600 pounds (270 kg) heavier than the Ferrari 330 P4's. During practice at Le Mans in 1967, in an effort to preserve the highly stressed brakes, Gurney developed a strategy (also adopted by co-driver A.J. Foyt) of backing completely off the throttle several hundred yards before the approach to the Mulsanne hairpin and virtually coasting into the braking area. This technique saved the brakes, but the resulting increase in the car's recorded lap times during practice led to speculation within the Ford team that Gurney and Foyt, in an effort to compromise on chassis settings, had hopelessly "dialed out" their car. The car proved to be fastest in a straight line that year, thanks to its streamlined aerodynamics, achieving 212 mph on the 3.6-mile Mulsanne Straight.

The Mk. IV ran in only two races, the 1967 12 Hours of Sebring and the 1967 24 Hours of Le Mans and won both events. Only one Mk.IV was completed for Sebring; the pressure from Ford had been amped up considerably after Ford's humiliation at Daytona two months earlier. Mario Andretti and Bruce McLaren won Sebring, Dan Gurney and A. J. Foyt won Le Mans (Gurney and Foyt's car was the Mk.IV that was apparently least likely to win), where the Ford-representing Shelby-American and Holman & Moody teams showed up to Le Mans with 2 Mk.IV's each.[27] The installation of the roll cage was ultimately credited by many with saving the life of Andretti, who crashed violently at the Esses during the 1967 Le Mans 24 Hours, but escaped with minor injuries.

Unlike the earlier Mk.I - III cars, which were built in England, the Mk.IVs were built in the United States by Kar Kraft. Le Mans 1967 remains the only all-American victory in Le Mans history—American drivers, team, chassis, engine, and tires. A total of six Mk IVs were constructed.[1] One of the Mk IVs was rebuilt to the Ford G7 in 1968, and used in the Can-Am series for 1969 and 1970, but with no success. This car is sometimes called the Ford Mk.IV.[1]

- MkV

For years Peter Thorp had searched for a GT40 in good condition. Most of the cars had problems including the dreaded rust issue. His company, Safir Engineering, was building and fielding Formula 3 race cars, in addition, had a Token Formula One car purchased from the Ron Dennis Company, Rondell Racing. Formula One events in which Safir Engineering competed included Brands Hatch and Silverstone. Safir was also redesigning Range Rovers modifying the unit to six-wheel drive and exporting them. Safir technical capabilities were such that they could rebuild GT40s. It was with this in mind that Thorp approached John Willment for his thoughts. It was soon decided that there would be a limited, further run of the significant GT40. JW Engineering would oversee the build, and Safir was to do the work. The continued JW Engineering/Safir Engineering production would utilize sequential serial numbers starting at the last used GT40 serial number and move forward. Maintaining the GT40 Mark nomenclature, this continued production would be named GT40 MkV.

JW Engineering wished to complete the GT40 chassis numbers GT40P-1087, 1088 and 1089. This was supposed to take place prior to the beginning of Safir production, however, the completion of these three chassis’ was very much delayed.

Ford's Len Bailey was hired to inspect the proposed build and engineer any changes he thought prudent to ensure the car was safe, as well as minimize problems experienced in the past. Baily changed the front suspension to Alan Mann specifications, which minimized nose-dive under braking. Zinc coated steel replaced the previous uncoated rust-prone sheet metal. The vulnerable drive donuts were replaced with CV joints and the leak-prone rubber gas tanks were replaced with aluminum tanks. The GT40 chassis was upgraded without making any major changes.

Tennant Panels supplied the roof structure and the balance of the chassis was completed by Safir. Bill Pink, noted for his electrical experience and the wiring installation of previous GT40s, was brought in. Also, Jim Rose was hired for his experience with working at both Alan Mann and Shelby. After the manufacture of chassis 1120, John Etheridge was hired to manage the GT40 build. The chassis was supplied from Adams McCall Engineering and parts supplied from Tennant panels.

For the most part, the MkV resembled very closely the MkI car, although there were a few changes, and, as with the 60s production, very few cars were identical.

The first car, GT40P-1090, had an open-top in place of roofed doors. Most motors were Ford small block, Webers or 4 Barrel Carburetor. Safir produced five Big Block GT40s, serial numbers GT40P-1128 to GT40P-1132. These aluminum big block cars all had easily removable door roof sections. Most GT40s were high-performance street cars however some of the MkV production can be described as full race. Two road cars GT40P-1133 (roadster) and GT40P-1142 (roofed doors) were built as lightweights which included an aluminum honeycomb chassis and carbon fiber bodywork.

Continuation models, replicas and modernizations[edit]

Several kit cars and replicas inspired by the Ford GT40 have been built. They are generally intended for assembly in a home workshop or garage. There are two alternatives to the kit car approach, either continuation models (exact and licensed replicas true to the original GT40) or modernizations (replicas with upgraded components, ergonomics & trim for improved usability, drivability, and performance).

- GT40/R Competition, United States: Authentic GT40 built by Superformance and co-designed with Pathfinder Motorsports. This is the only GT40 continuation licensed by Safir GT40 Spares LLC, the holders of the GT40 trademark. A GT40/R (GT40P/2094) campaigned by Pathfinder Motorsports with an engine built by Holman Moody won both the 2009 US Vintage Grand Prix and the 2009 Governor's Cup at Watkins Glen.[28]

- Southern GT: Built-in Botley, Southampton, UK. Specializing in GT40 Mk1 and Mk2, as well as Lola T70. Kit form or fully built to your specifications.

- CAV GT: Originally designed for customers to build as a kit, the CAV GT has evolved into a modernized replica that is now factory-built in Cape Town, South Africa.

- Holman Moody: GT40 Mark II won third at Le Mans in 1966, and can still manufacture a Holman GT from 1966 blueprints.

- GT40 Spyder, United States: Built by E.R.A. Replica Automobiles in New Britain, CT, the Spyder is a MK2 Canadian American (CAN-AM) racing replica.[29]

Ford GT

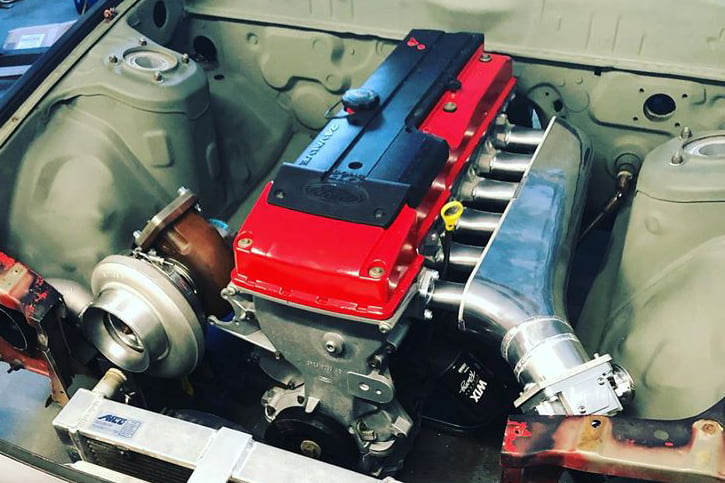

An Australian In The States — Building A Ford Barra In The U.S.

When you think of an “import” engine, you often think Japanese or European. When you add in the qualifiers of “inline-six” and “never available in the United States,” chances are your mind races to something like the Japanese Nissan RB series of engines. Certainly not an Australian engine, and certainly not something with a Blue Oval on the valve cover, right?

Over the past few years, it seems like Ford Australia’s hidden gem (at least in the U.S. market) has become less of a secret. We’ve seen several sources for the importation of the Barra engine pop-up in the last year. For the uninitiated, the Ford Barra family of engines were inline-six and V8 engines from Ford Australia manufactured from 2002 through 2016.

More often than not, “Barra” refers to one of the 4.0-liter, inline-six-cylinder variants of the engine. From the factory, all of the Barra engine variants come with a dual-overhead-camshaft cylinder head with four valves per cylinder and variable camshaft timing. The engines came in a number of naturally aspirated options ranging from 244 to 288 horsepower, and turbocharged variants ranging from 322 to 436 horsepower in OEM trim.

When it comes to modern inline-six-cylinder powerhouses, Ford isn’t usually the first manufacturer to come to mind. However, the Australian Barra engine is a stout platform on which to build.

A Booming Aftermarket

Obviously, any engine with these kinds of chops from the factory is more likely to enjoy a very healthy dose of aftermarket support. The Barra is no different, other than never being exported outside of Australia by Ford. However, that hasn’t stopped them from showing up in the U.S. As you’re about to see, us Yanks can turn them into serious powerhouses, too.

What started merely as a fascination for Chris Porter, the owner of Forced Induction Pros, has ended up turning into quite an impressive project. One which has the potential to expose a whole new segment of enthusiasts to the modern Blue-Oval inline-six; the Barra.

There is not much Voodoo going on here, the engine is simply beefy. – Jimmy Bowling, Buschur Racing

“Over years of watching videos on YouTube, I was interested in a big inline-six making big power,” says Porter. “I had the RX-7 set up for a 4G63 when a Barra engine turned up in Florida. It was my chance to compete with bigger displacement cars, without having to do a cookie-cutter 2JZ or LS build. It seemed like it was meant to be, so I jumped in blind and hoped for the best.”

In order to turn the stock Barra engine into a suitable four-digit-horsepower monster, Porter turned to someone well-known to us, Jimmy Bowling of Buschur Racing. He might be familiar to many of you as the engine-builder for Team Stinky Pinky from Season 1 of Horsepower Wars $10K Drag Shootout.

While the Barra is a well-served platform, getting those parts into the U.S. can be a bit of a challenge — one that Bowling was more than up to taking on. In fact, this project has actually opened up some new sources for Barra parts in the U.S. “A lot of the engine internals can now be purchased through us here in the States from a lot of the main engine parts suppliers,” says Bowling.

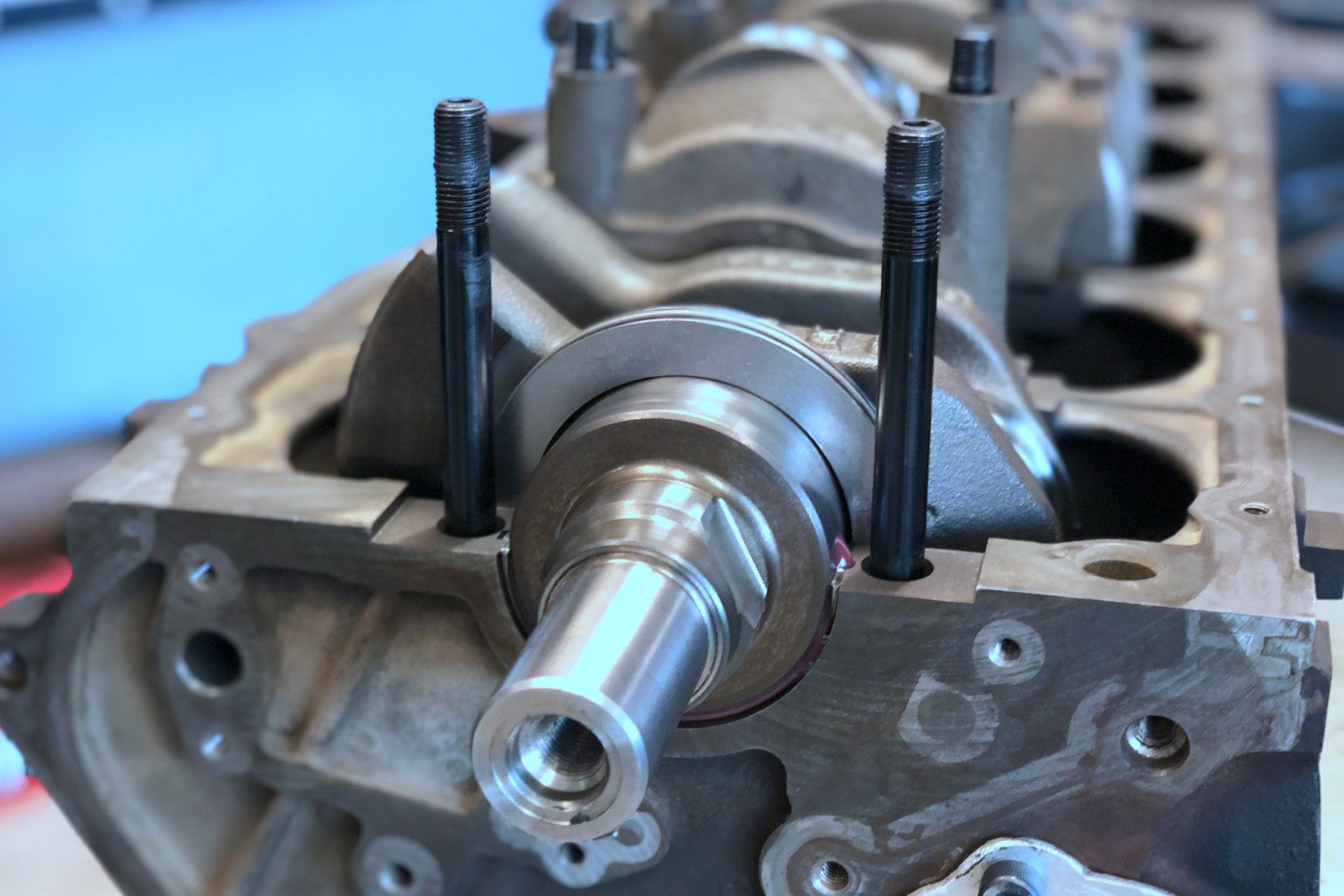

Bowling did a full Hard Blok fill on the Barra’s OEM block before machining. As you can see, the cylinders also got a fresh hone after the .030-inch overbore, for a final bore size of 3.652 inches.

Going Down Under

Starting with an OEM Barra block, Bowling performed a full Hard Blok fill to ensure that the OEM block would hold up to the rigors imparted by well-north of 1,000 horsepower. Once All In Racing Engines — another of Bowling’s enterprises — finished machining the block, in went the OEM Barra crankshaft. Using an OEM crank was a calculated risk taken by Porter, after much deliberation.

“Results seem to vary,” says Porter. “But, I have seen Benny’s Custom Works Cresta make 1,247 whp on a stock crank, and Corey Darke’s Mustang make 1,800 wheel-horsepower on a stock crank. Billet options are available, but that didn’t seem necessary just yet.”

It was a calculated choice to use the stock crankshaft, as the beefy OEM unit has been proven to upwards of 1,800 wheel-horsepower. Upgrading to ARP main studs also helps increase the power-holding ability of the stock parts.

The OEM crankshaft rides on a set of ACL race bearings in the mains as well as in the CP-Carrillo Bullet-Series connecting rods. Made from forged 4330M steel, the U.S.-made Bullet rods come outfitted with H-11 tool-steel fasteners and a design that maximizes strength while minimizing weight.

Attached to those are custom CP pistons, which measure 3.652 inches in diameter (.030 inch larger than stock), which only stands to reason, given the rods being used. Made from 2618 aluminum, the pistons feature CP’s clip-cuts to deburr and unshroud the valves. CP provided a plasma-moly-coated ductile-iron top ring, a cast-iron taper-faced second ring, and standard-tension oil rings.

Using beefy 0.180-inch-wall CP 9310 steel wrist pins to connect the pistons to the rods, there should be no problem handling all the cylinder pressure the turbo can make. Providing oil to the combination is an OEM Ford oil pump housing, outfitted with Boundry Pump Divison billet-steel replacement gears, coupled with the OEM pickup and pan.

All said and done, the short-block measures out to just over 245 cubic inches (or 4.027 liters) of displacement from the factory 3.910 stroke and .030-inch overbore.

CP-Carrillo was the go-to for rods and pistons. Using Carriillo Bullet-series rods, .180-inch-wall wrist pins, and custom CP pistons with CP’s ring pack, the assembly should be able to handle all the power thrown at it with ease.

Barra Top End

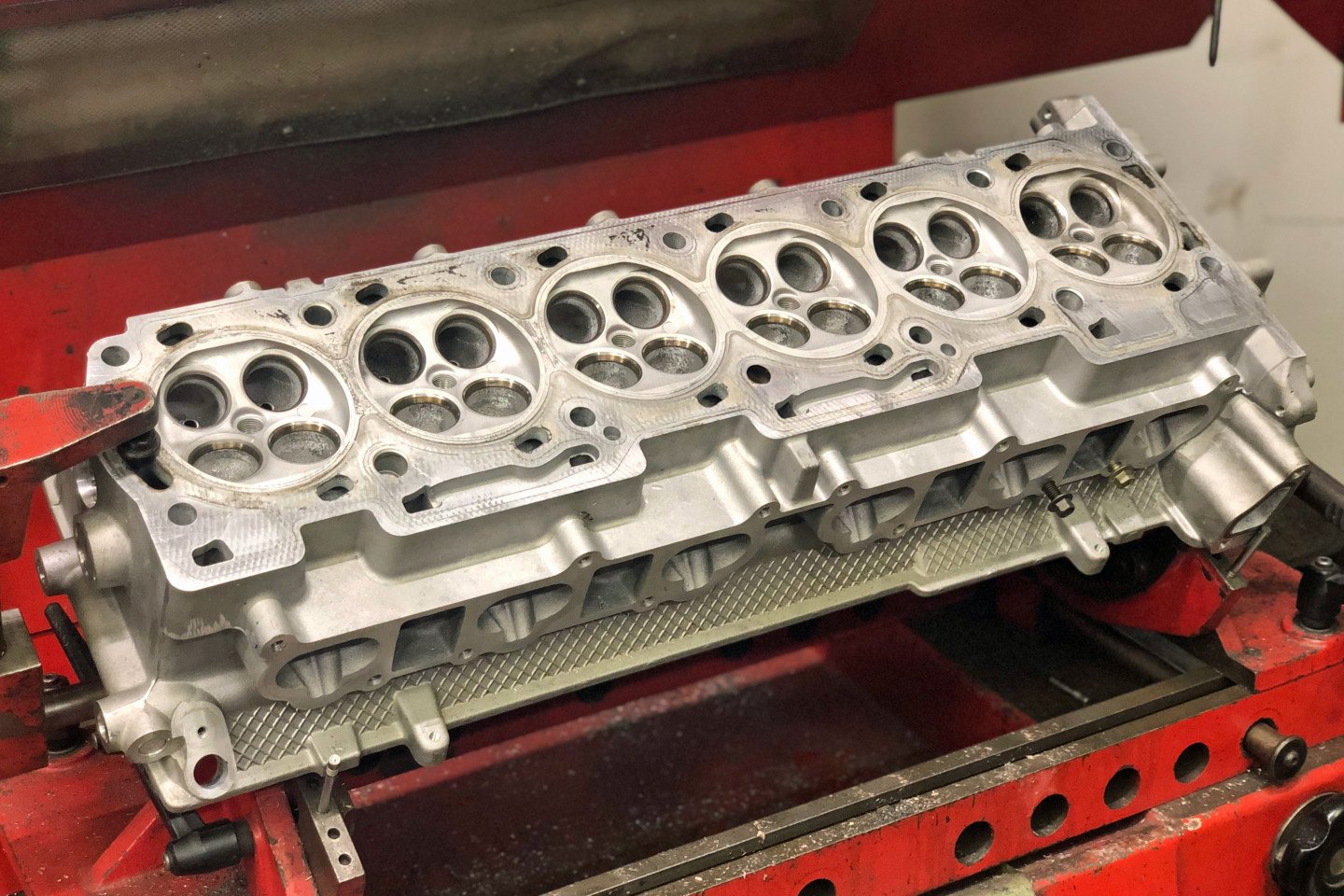

Starting with an OEM Barra cylinder head, Bowling performed some pocket porting by hand. Then Bowling fitted a set of Supertech EV8 stainless-steel intake valves, coated with Black Nitride. “Nitrided valves offer a higher surface hardness while maintaining ductility of the stainless steel, so they are not brittle,” says Bowling. “They also offer a smoother surface finish resulting in less friction in the guide.”

On the exhaust side, in preparation for a significant amount of boost, Bowling opted for Inconel 751 (nickel-based alloy) exhaust valves. To control the valves, a set of Supertech’s Beehive springs with 91 pounds of pressure on the seat were used, along with the associated steel retainers.

The Barra’s cylinder head received a pocket port and some valve seat work to accommodate the Supertech nitrided stainless-steel intake and Inconel exhaust valves.

Topping off the cylinder heads are a set of Atomic Performance Products Stage 5 Battlemaster camshafts with .510-inch of lift on both intake and exhaust along with 241 degrees of intake duration at .050-inch, and 236 degrees of exhaust at .050.

The suggested camshaft lobe separation is 112 to 114 degrees. To achieve that, Bowling opted for a set of Atomic Perormance’s Vernier-adjustable camshaft sprockets with an OEM timing chain. Factory Barra 2.04:1 rocker arms and hydraulic lifters round out the impressive valvetrain.

Holding the cylinder head to the block is an off-the-shelf product in Austrailia that had to be shipped over — a set of Atomic H-13 tool steel head studs. However, Bowling has since worked with ARP to be able to offer U.S.-made kits to domestic customers. So they will now be an off-the-shelf part here in the States, as well.

Complementing the aggressive cams, are OEM Ford 2.04:1 rocker arms and hydraulic lifters. It might seem odd, but it’s a proven combination Down Under.

Fuel, Air, and Spark

The other star of this engine combination is the BorgWarner S400 80mm SX-E turbocharger. Pushed hard, it will make an expected 40psi of boost. In order to funnel all of that boost into the Barra’s intake ports, Bowling opted for a Hypertune intake manifold kit from Australia, fitted with a 90mm K-Tuned throttle body.

Feeding the turbine side of the turbocharger is a custom-fabricated turbo manifold from Forced Induction Pros. At the same time, an Aeromotive mechanical fuel pump and fuel pressure regulator combination will keep the Fuel Injector Development 2,000 cc/min fuel injectors fed with One Ethanol R fuel. IGN-1A smart coils will keep the spark lit, while a FuelTech FT500 controls everything.

Bowling feels the engine should support 1,500-plus horsepower easily. Now, having built one, he has more insight into the Barra. “I would advise the average homebuilder, or even a shop for that matter, to make friends with some Australians,” says Bowling. “But, there is not much Voodoo going on here, the engine is simply beefy. There are even some things I picked up on that are similar to other Ford products, such as the Modular engines.”

Porter agrees, saying: “It is a very long and large engine, but at the end of the day, it’s not as exotic as everyone makes it seem. The biggest hurdles currently are most everyday gaskets and replacement parts are in Australia. With that said, the community of trusted members is continuing to grow, and parts for the Barra will become more available as time goes on.”

As fans of the Barra, we’ll be watching along as Porter buttons up the final details of the car and gets the combination on the dyno. We’re excited to see this particular engine’s numbers, as well as an overall increase in the American popularity of Ford Australia’s inline-six.

The Barra engine will initially be force-fed 40 pounds of boost by a BorgWarner 80mm S400 SX-E turbocharger. After initial testing, that might change, but Bowling says that the engine should be able to handle 1,500-plus horsepower with ease.

No comments:

Post a Comment