or reload the browser

or reload the browser

When you think of an “import” engine, you often think Japanese or European. When you add in the qualifiers of “inline-six” and “never available in the United States,” chances are your mind races to something like the Japanese Nissan RB series of engines. Certainly not an Australian engine, and certainly not something with a Blue Oval on the valve cover, right?

Over the past few years, it seems like Ford Australia’s hidden gem (at least in the U.S. market) has become less of a secret. We’ve seen several sources for the importation of the Barra engine pop-up in the last year. For the uninitiated, the Ford Barra family of engines were inline-six and V8 engines from Ford Australia manufactured from 2002 through 2016.

More often than not, “Barra” refers to one of the 4.0-liter, inline-six-cylinder variants of the engine. From the factory, all of the Barra engine variants come with a dual-overhead-camshaft cylinder head with four valves per cylinder and variable camshaft timing. The engines came in a number of naturally aspirated options ranging from 244 to 288 horsepower, and turbocharged variants ranging from 322 to 436 horsepower in OEM trim.

When it comes to modern inline-six-cylinder powerhouses, Ford isn’t usually the first manufacturer to come to mind. However, the Australian Barra engine is a stout platform on which to build.

Obviously, any engine with these kinds of chops from the factory is more likely to enjoy a very healthy dose of aftermarket support. The Barra is no different, other than never being exported outside of Australia by Ford. However, that hasn’t stopped them from showing up in the U.S. As you’re about to see, us Yanks can turn them into serious powerhouses, too.

What started merely as a fascination for Chris Porter, the owner of Forced Induction Pros, has ended up turning into quite an impressive project. One which has the potential to expose a whole new segment of enthusiasts to the modern Blue-Oval inline-six; the Barra.

There is not much Voodoo going on here, the engine is simply beefy. – Jimmy Bowling, Buschur Racing

“Over years of watching videos on YouTube, I was interested in a big inline-six making big power,” says Porter. “I had the RX-7 set up for a 4G63 when a Barra engine turned up in Florida. It was my chance to compete with bigger displacement cars, without having to do a cookie-cutter 2JZ or LS build. It seemed like it was meant to be, so I jumped in blind and hoped for the best.”

In order to turn the stock Barra engine into a suitable four-digit-horsepower monster, Porter turned to someone well-known to us, Jimmy Bowling of Buschur Racing. He might be familiar to many of you as the engine-builder for Team Stinky Pinky from Season 1 of Horsepower Wars $10K Drag Shootout.

While the Barra is a well-served platform, getting those parts into the U.S. can be a bit of a challenge — one that Bowling was more than up to taking on. In fact, this project has actually opened up some new sources for Barra parts in the U.S. “A lot of the engine internals can now be purchased through us here in the States from a lot of the main engine parts suppliers,” says Bowling.

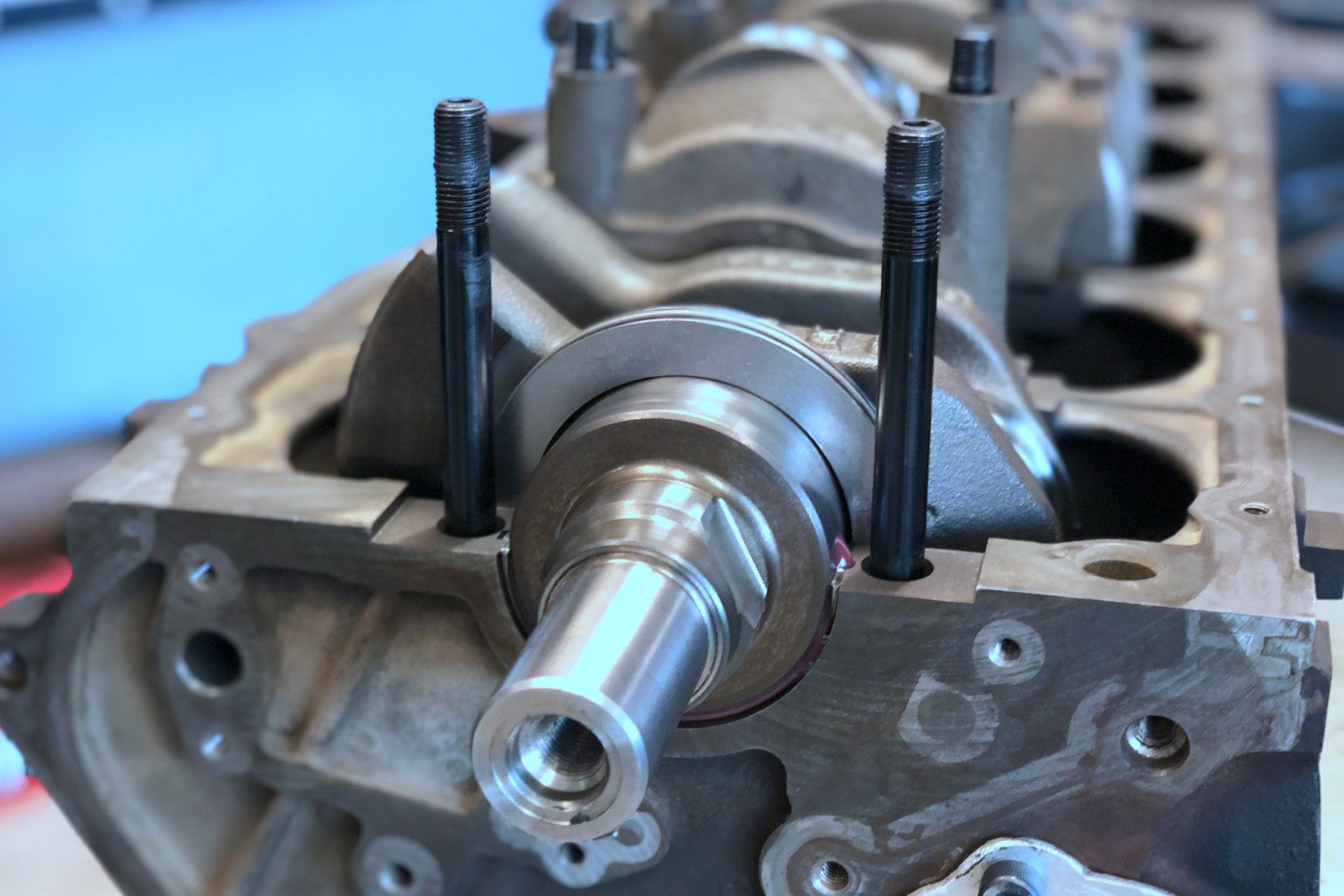

Bowling did a full Hard Blok fill on the Barra’s OEM block before machining. As you can see, the cylinders also got a fresh hone after the .030-inch overbore, for a final bore size of 3.652 inches.

Starting with an OEM Barra block, Bowling performed a full Hard Blok fill to ensure that the OEM block would hold up to the rigors imparted by well-north of 1,000 horsepower. Once All In Racing Engines — another of Bowling’s enterprises — finished machining the block, in went the OEM Barra crankshaft. Using an OEM crank was a calculated risk taken by Porter, after much deliberation.

“Results seem to vary,” says Porter. “But, I have seen Benny’s Custom Works Cresta make 1,247 whp on a stock crank, and Corey Darke’s Mustang make 1,800 wheel-horsepower on a stock crank. Billet options are available, but that didn’t seem necessary just yet.”

It was a calculated choice to use the stock crankshaft, as the beefy OEM unit has been proven to upwards of 1,800 wheel-horsepower. Upgrading to ARP main studs also helps increase the power-holding ability of the stock parts.

The OEM crankshaft rides on a set of ACL race bearings in the mains as well as in the CP-Carrillo Bullet-Series connecting rods. Made from forged 4330M steel, the U.S.-made Bullet rods come outfitted with H-11 tool-steel fasteners and a design that maximizes strength while minimizing weight.

Attached to those are custom CP pistons, which measure 3.652 inches in diameter (.030 inch larger than stock), which only stands to reason, given the rods being used. Made from 2618 aluminum, the pistons feature CP’s clip-cuts to deburr and unshroud the valves. CP provided a plasma-moly-coated ductile-iron top ring, a cast-iron taper-faced second ring, and standard-tension oil rings.

Using beefy 0.180-inch-wall CP 9310 steel wrist pins to connect the pistons to the rods, there should be no problem handling all the cylinder pressure the turbo can make. Providing oil to the combination is an OEM Ford oil pump housing, outfitted with Boundry Pump Divison billet-steel replacement gears, coupled with the OEM pickup and pan.

All said and done, the short-block measures out to just over 245 cubic inches (or 4.027 liters) of displacement from the factory 3.910 stroke and .030-inch overbore.

CP-Carrillo was the go-to for rods and pistons. Using Carriillo Bullet-series rods, .180-inch-wall wrist pins, and custom CP pistons with CP’s ring pack, the assembly should be able to handle all the power thrown at it with ease.

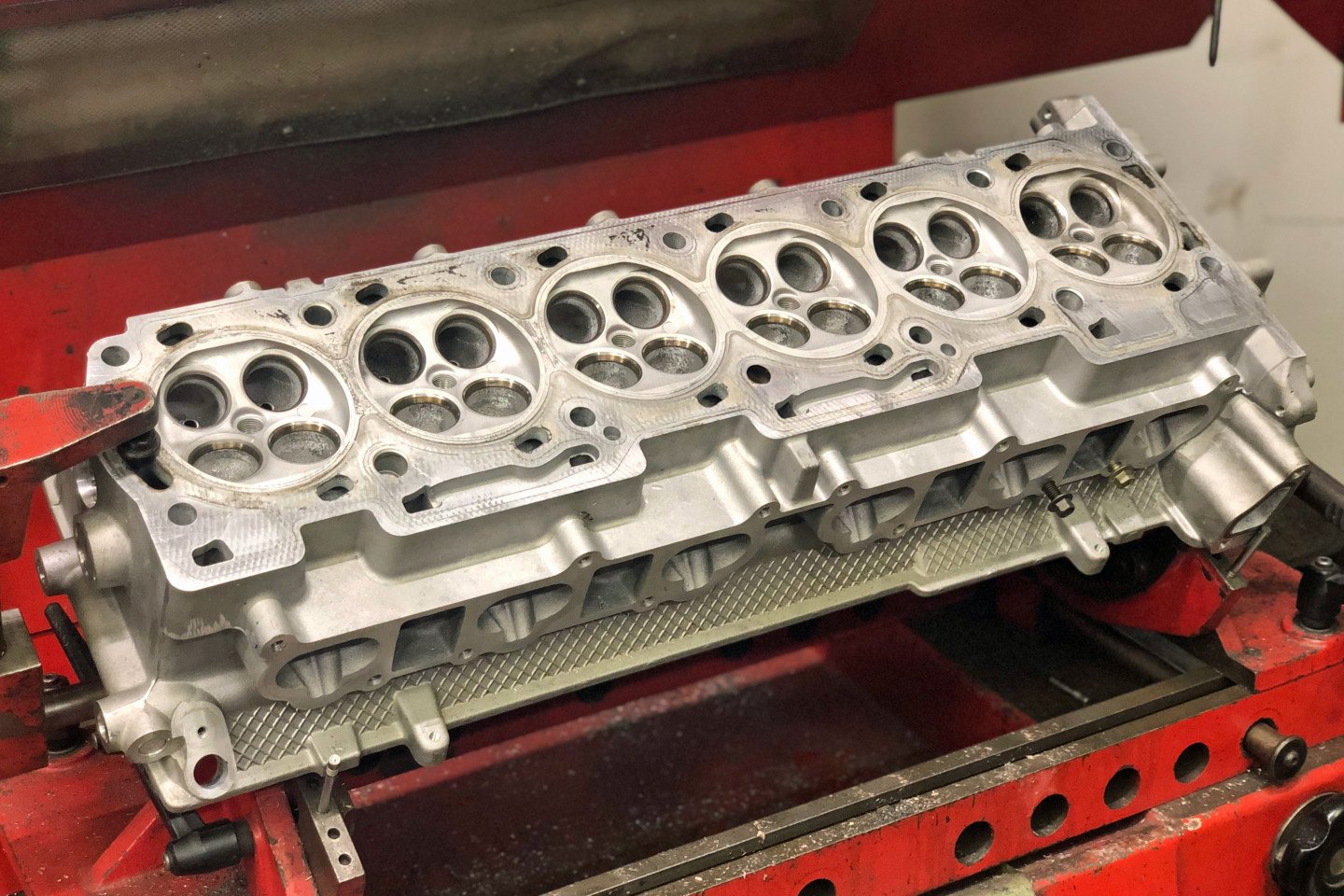

Starting with an OEM Barra cylinder head, Bowling performed some pocket porting by hand. Then Bowling fitted a set of Supertech EV8 stainless-steel intake valves, coated with Black Nitride. “Nitrided valves offer a higher surface hardness while maintaining ductility of the stainless steel, so they are not brittle,” says Bowling. “They also offer a smoother surface finish resulting in less friction in the guide.”

On the exhaust side, in preparation for a significant amount of boost, Bowling opted for Inconel 751 (nickel-based alloy) exhaust valves. To control the valves, a set of Supertech’s Beehive springs with 91 pounds of pressure on the seat were used, along with the associated steel retainers.

The Barra’s cylinder head received a pocket port and some valve seat work to accommodate the Supertech nitrided stainless-steel intake and Inconel exhaust valves.

Topping off the cylinder heads are a set of Atomic Performance Products Stage 5 Battlemaster camshafts with .510-inch of lift on both intake and exhaust along with 241 degrees of intake duration at .050-inch, and 236 degrees of exhaust at .050.

The suggested camshaft lobe separation is 112 to 114 degrees. To achieve that, Bowling opted for a set of Atomic Perormance’s Vernier-adjustable camshaft sprockets with an OEM timing chain. Factory Barra 2.04:1 rocker arms and hydraulic lifters round out the impressive valvetrain.

Holding the cylinder head to the block is an off-the-shelf product in Austrailia that had to be shipped over — a set of Atomic H-13 tool steel head studs. However, Bowling has since worked with ARP to be able to offer U.S.-made kits to domestic customers. So they will now be an off-the-shelf part here in the States, as well.

Complementing the aggressive cams, are OEM Ford 2.04:1 rocker arms and hydraulic lifters. It might seem odd, but it’s a proven combination Down Under.

The other star of this engine combination is the BorgWarner S400 80mm SX-E turbocharger. Pushed hard, it will make an expected 40psi of boost. In order to funnel all of that boost into the Barra’s intake ports, Bowling opted for a Hypertune intake manifold kit from Australia, fitted with a 90mm K-Tuned throttle body.

Feeding the turbine side of the turbocharger is a custom-fabricated turbo manifold from Forced Induction Pros. At the same time, an Aeromotive mechanical fuel pump and fuel pressure regulator combination will keep the Fuel Injector Development 2,000 cc/min fuel injectors fed with One Ethanol R fuel. IGN-1A smart coils will keep the spark lit, while a FuelTech FT500 controls everything.

Bowling feels the engine should support 1,500-plus horsepower easily. Now, having built one, he has more insight into the Barra. “I would advise the average homebuilder, or even a shop for that matter, to make friends with some Australians,” says Bowling. “But, there is not much Voodoo going on here, the engine is simply beefy. There are even some things I picked up on that are similar to other Ford products, such as the Modular engines.”

Porter agrees, saying: “It is a very long and large engine, but at the end of the day, it’s not as exotic as everyone makes it seem. The biggest hurdles currently are most everyday gaskets and replacement parts are in Australia. With that said, the community of trusted members is continuing to grow, and parts for the Barra will become more available as time goes on.”

As fans of the Barra, we’ll be watching along as Porter buttons up the final details of the car and gets the combination on the dyno. We’re excited to see this particular engine’s numbers, as well as an overall increase in the American popularity of Ford Australia’s inline-six.

The Barra engine will initially be force-fed 40 pounds of boost by a BorgWarner 80mm S400 SX-E turbocharger. After initial testing, that might change, but Bowling says that the engine should be able to handle 1,500-plus horsepower with ease.